Designed to give you the greatest amount of versatility, value and performance. Pope is excited to share the latest in Cannabis Distillation Systems.

The concept of two passes for the distillation of cannabinoids is understood by many; one pass for devolatilizing or ridding the feed material of gasses, ethanol, water, light terpene ends, etc., so that the next, cannabinoid distillation pass can be performed with greater vacuum, throughput, purity, yield, and product clarity. So why four passes? To accommodate the widest ranges in starting materials, extraction methods and other pre-distillation steps, and optimization of throughput and choices of finished products.

Different operating modes are incorporated for this:

- Extended Purity and Yield Modes. Feed enters stage 1 for devolatilizing/degassing, with residue passing to stage 2 for the cannabinoid distillation pass. The process can stop there or continue with stage 2 residue passing to stage 3 for a “second squeeze” to collect additional undistilled cannabinoids, thus increasing overall yield. The distillate from stage 2 can pass to stage 4 for re-distillation for increased product purity well into the nineties in the percentage of cannabinoids. These transfers from stage 2 onwards can be selected by the operator to be both, choice of only one, or not at all, depending on the goals of the company.

- Double Devolatilization Modes, whereby stages 1 and 2 are both used to strip off light ends. This is especially important where the volatiles such as ethanol have not been sufficiently removed beforehand, one of the most common missteps in processing. (5% solvent, for example, is too much for a proper 1st pass, 0.5% is better). Feed enters stage 1 for removal of gasses and excess solvent and is then passed to stage 2 for a deeper cut, with the removal of any remaining solvents and stripping off and collecting terpenes. Cannabinoid distillation will now run much better, starting in stage 3. The process can end there or otherwise continue on to stage 4, with stage 3 residue passed forward for a second squeeze for increased yield, or else with stage 3 distillate, for re-distillation for increased product purity well into the nineties in percentage cannabinoids.

- Parallel Mode, for when double devolatilization is not required and the four-stage system can operate as two separate two-stage systems, both operated from the same control system. Twice the overall throughput is possible compared to a two-stage canna distillation system. As an example, a four-stage 6” size still can process 20 kg/hr while its two-stage sibling would process 10 kg/hr. This mode alone, with double the throughput, can justify procurement of a four-stage system, but along with this comes the inherent versatility of the alternate modes of operation also being available to the operator.

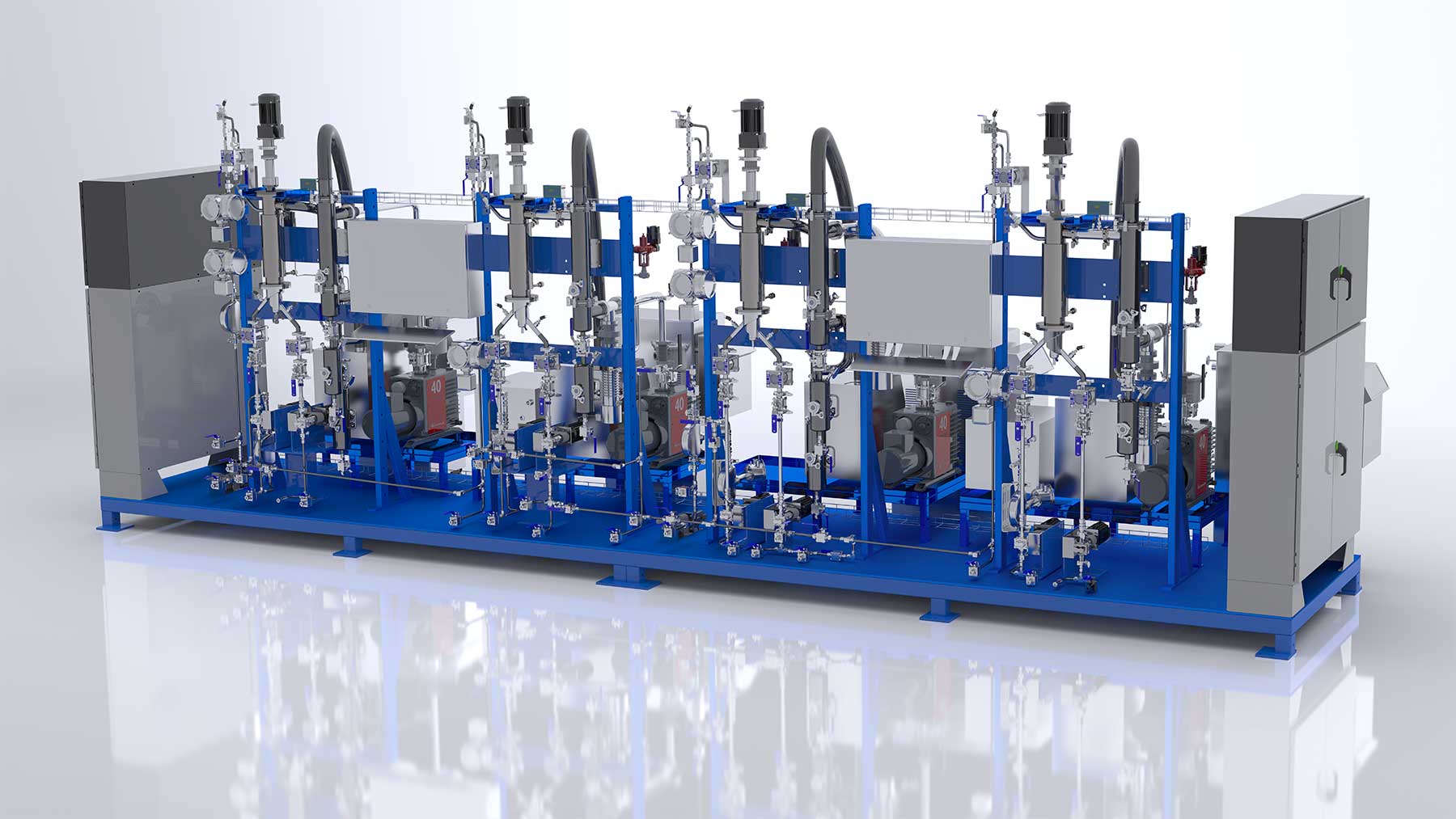

Pope four-stage 4″ Wiped Film Still System

Pope’s four-stage turnkey systems, just like the two or three-stage turnkey systems, are operated with A-B Rockwell PLC control systems and large PC computer-based HMI (human-machine interface) touchscreens. The four-stage version also comes with an additional HMI. All control, alarm, setpoint, and mode selection and maintenance are handled through the HMI, with different levels of password protection. In addition, all Pope systems feature a powerful data storage and display program that can be popped up and superimposed on the HMI as a Windows window. The storage capacity is huge, and the recordings can easily be scrolled back to quickly view and compare weeks or months of operating records. Groupings of data points can be selected as desired, with readings and trend lines of multiple instrumentation ranges easily visible simultaneously; for example, several temperature points, flow rates, and vacuum levels, and for any time period. Data can also be passed along to other devices such as DCS or computers in various ways including ethernet networking.

A hallmark feature with Pope is that every turnkey system incorporates a highly accurate Coriolis flow meter in the initial feed line, with a feedback loop to the feed-pump’s motor to keep the process rock steady. (Of course, other parameters such as temperatures and vacuum levels are similarly feedback controlled). As an option, additional Coriolis flowmeters can be added to discharge/transfer lines to allow the operator to read flow rates through the entire system, with the HMI also indicating in real time, the percent distillate splits, extremely useful indicators of how much of the feed is being distilled off. This often-overlooked parameter can make a major difference in optimization of the distillation process. And because it’s read in real-time, (no more stopwatches and collection flask drudgery), changes can be made and observed on the fly; for example, if the split percentage is a bit too low, the operator can tweak the body temperature up a couple of degrees to bring it to the desired level.

In addition to 2-D CAD, Pope’s engineers also utilize SolidWorks for 3-D design of components and complete turnkey multistage systems. The drawing shown is a detailed rendering of a four-stage, 4” distillation system currently in fabrication at Pope.