Understanding the difference between short-path, fractional and Pope’s wiped-film molecular stills:

Oftentimes when people are considering distillation equipment for processing hemp and cannabis, there seems to be a lot of confusion and misuse of terminology with short-path stills and Pope’s wiped-film molecular stills. While this is covered in our FAQs section, we have explored some of the key points below.

What is Molecular Distillation?

Molecular distillation and short-path distillation are the same things. These both imply the use of high vacuum and a condensing surface in close proximity to a heated evaporation surface. For many applications such as cannabinoids and as well as other compounds with greater molecular weight and boiling points, if the distance is not close enough, the equipment will not work well, if at all.

What does short-path mean?

We discovered some people perceive the term “short-path” to imply a basic glassware setup involving a basic boiling flask with a neck leading to a condenser and a receiver flask(s), or else a similar variation called a KIugelrohr. These are oftentimes also referred to as pot stills, (pot as in a vessel, not in the cannabis sense), and are all considered batch mode apparatus. However, these only refer to one type (the simplest type) of short-path or molecular stills. There are other forms of short-path setups including Pope’s continuous mode Wiped-Film Molecular Still (WFMS).

Is a fractional still the same thing as a short-path still?

Fractional stills are not short-path stills. Fractional distillation equipment implies the utilization of a vertical packed column providing multiple equilibrium stages or “theoretical plates”, requiring the condenser to be further away from the boiling container (reboiler) and reached only after the obstacle of the packed column. While this can be used to increase the purity of a distillate, it is instead a problem for heat-sensitive materials such as cannabinoids. Though Pope does offer fractional distillation equipment, the single theoretical plate of molecular stills is sufficient for most cannabinoid work and offers the least product degradation.

Image source: http://www.chemhelper.com/distillation.html

What are the advantages of a wiped-film still compared to a boiling flask short path setup?

Now that we have a good understanding of short path, we want to dive into the advantages of Pope’s WFMS over a basic boiling flask type molecular short path still. One key advantage is that the Pope WFMS is a continuous mode, rather than batch mode still. This means that with larger or special flasks, or with liquid pumps, they can operate for extended periods of time with any quantity of feed material and with the same consistent product composition over time. The Pope WFMS is also scalable, such that when much larger quantities of material needs to be processed, larger versions of the same type of equipment can be utilized to accommodate the greater throughputs required. Batch mode stills such as the boiling flask short path still can be scaled but lose efficiencies due to heat and mass transfer limitations resulting in extremely long operation times and loss of product to degradation.

In addition to scalability and continuous mode, another advantage is the Pope WFMS offers much less thermal degradation and greater product purity and yield. This is for two reasons. One, there is a very short residence exposure time to a heated surface – only a matter of seconds, compared to many hours in a boiling flask molecular still. And two, the WFMS has a highly efficient dynamic rotating wiped film action providing turbulent moving thin-film mixing compared to the limited, less dynamic liquid/vapor interface of a simple boiling flask apparatus.

Have more questions on terminology or Pope’s Wiped-Film Molecular stills? We are here to help answer your questions. Contact us to learn more or speak with a Pope team member.

Pope 2″ Wiped-film Molecular Still

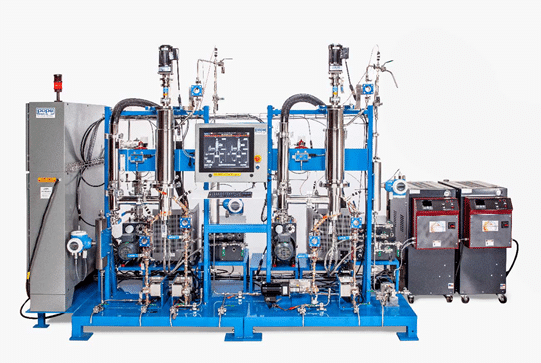

Pope 2 Stage 6″ in Turnkey Canna Wiped-Film Still with Hot Oil